Imposition

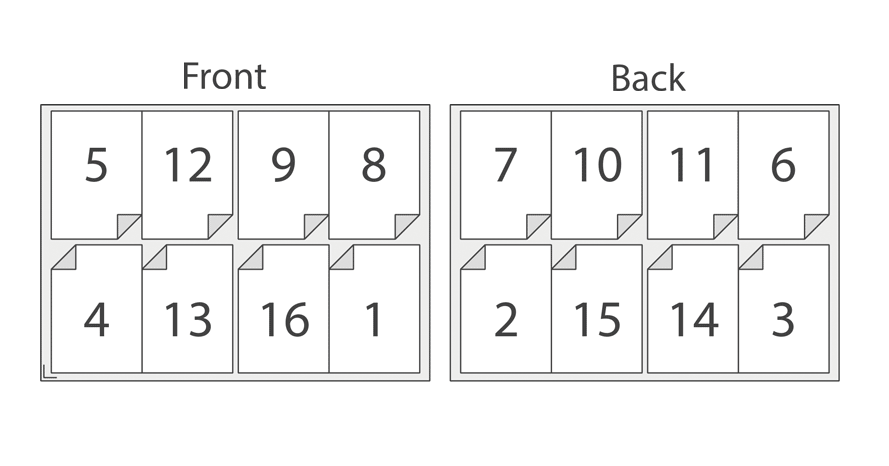

In books printing, imposition refers to the arrangement and positioning of pages on a press sheet in a specific order and layout so that when the sheet is printed, folded, and trimmed, the pages will appear in the correct sequential order in the finished product, such as a booklet, magazine, or brochure.

In packaging printing, imposition refers to the arrangement and positioning of packaging elements. It involves determining how the packaging components will be laid out on the printing substrate.

(Pages imposition)

(Press sheet)

The goal of imposition in book printing is to optimize the use of paper, minimize waste, and ensure that the pages are correctly positioned for efficient printing and binding. It involves determining how many pages can fit on a single press sheet, how they should be arranged, and how the sheet should be folded or trimmed to create the final product.

(Press sheet)

Imposition in packaging printing is also essential. It helps minimize the amount of material (e.g., paperboard) required for production, reducing costs and waste. The layout created during imposition also takes into account the placement of die-cutting lines, perforations, folds, and other finishing details, making it easier to produce the final packaging. In addition, it improves production speed, as it minimizes the number of required setup changes and reduces downtime during converting and finishing processes.

Overall, imposition is a critical step in the pre-press workflow to ensure that the printed materials are produced correctly and efficiently.

Copyright © 2003-2024 Sunvandar Printing Co., Ltd. All rights reserved.

Factory Address

Block D3, Shanglilang industrial estate, Pingji Blvd, Long gang district, Shenzhen, China, 518112

Follow Sunvandar

sales@sunvandar.com